With the widespread adoption of digital printing technology, an increasing number of textile manufacturers are leveraging digital printers to enhance production efficiency and product quality. However, many enterprises have observed a gradual rise in waste ink generation during operation. This issue not only escalates production costs but also poses potential environmental contamination risks. What, then, are the underlying causes of increased waste ink in digital textile printers?

-

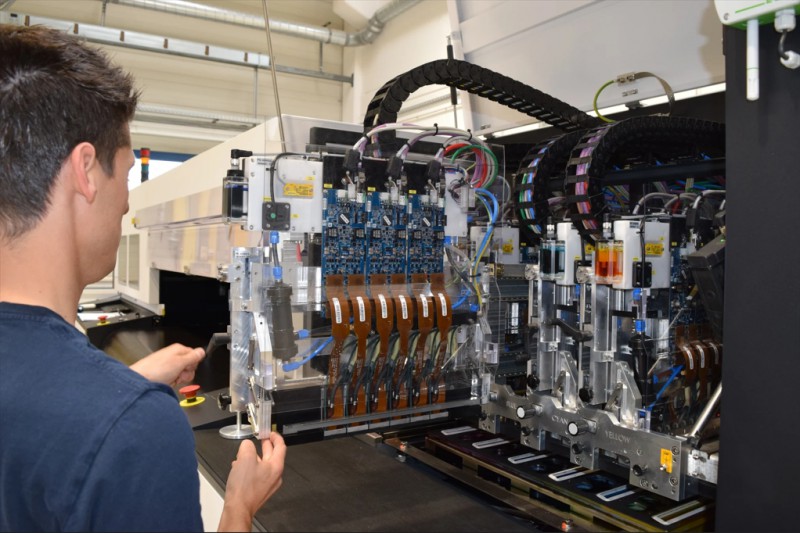

Print Head Clogging or Wear

The print head serves as the core component for inkjet propulsion, with its operational condition directly influencing ink utilization efficiency. Clogged or worn print heads can cause uneven ink distribution, compromising print quality. To maintain optimal performance, the machine may initiate automatic cleaning cycles, expending significant amounts of ink to clear nozzle blockages, thereby substantially increasing waste ink generation 1. -

Ink-Substrate Incompatibility

Different ink formulations are tailored for specific substrate types. Mismatched ink-substrate combinations often lead to issues like color bleeding or poor adhesion. Achieving desired print results may require repeated parameter adjustments or ink replacements, generating substantial waste ink during these processes. Additionally, the machine may apply excess ink to compensate for color inconsistencies, further exacerbating waste 1. -

Inaccurate Color Management & Improper Settings

Precise color management is critical in digital printing. Inaccurate color profiles or flawed settings can result in color deviations, necessitating multiple calibration trials. These test prints inherently waste ink. Furthermore, excessive color saturation or unnecessary layering amplifies ink consumption, contributing to higher waste volumes 1. -

Insufficient Equipment Maintenance

Regular maintenance is essential for sustaining printer functionality. Neglected or inadequate upkeep can damage components like print heads and ink systems. For example, air bubbles or sediment in ink lines disrupt ink flow, degrading print quality. Repeated cleaning or part replacements to restore performance generate additional waste ink 1. -

Excessive Cleaning Cycles

Digital printers perform periodic automatic cleaning to maintain nozzle precision. However, overly frequent cycles—particularly after prolonged machine inactivity—consume excessive ink to revive print head functionality, significantly increasing waste 1. -

Complex Printing Tasks

Highly detailed designs with intricate patterns and vibrant color palettes demand higher ink volumes. Repeated revisions or corrections to such tasks multiply ink consumption through redundant prints. Moreover, complex color layering and intricate detailing in advanced designs further drive up waste ink production 1.

The surge in waste ink stems from a confluence of factors: print head performance, ink-substrate compatibility, color management precision, maintenance diligence, and task complexity. To mitigate this issue, enterprises should prioritize routine equipment maintenance, select appropriate ink-substrate pairs, optimize printing parameters, and train operators in professional color management and equipment handling. These measures not only reduce operational costs but also minimize environmental impact, fostering sustainable development 1.

Reprinted from http://www.inknet.cn/