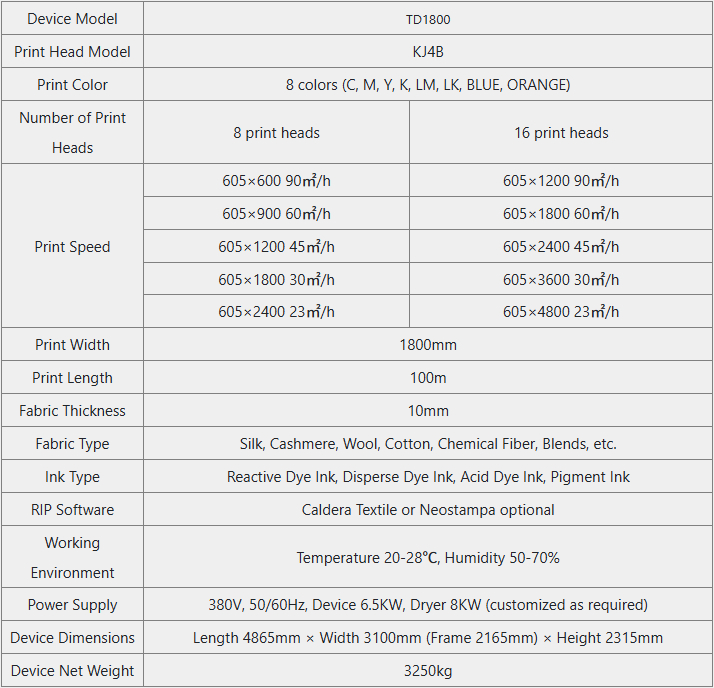

TD1800

Has two production lines, several sets of stamping equipment. Company to ensure product quality is equipped with a variety of testing equipment, electronic tensile testing machine, fatigue testing machine. Products and industry international brands, domestic brands long-term cooperation.

Interpretation of Equipment Advantages

- Printing Structure: A double-sided printing structure with two sets of printing carts, completing the double-sided printing process in one go.

- Synchronous Printing: Synchronous data transmission control ensures that both sets of carts print simultaneously.

- Automatic Alignment: Real-time collection of printed images, automatic correction of printing data, eliminating the need for manual intervention in the alignment printing process.

- Tension Release: Servo constant tension release mechanism, fabric tension remains unchanged regardless of the size of the fabric roll.

- Tension Parameters: Different tension parameters set for different fabrics, programs can be stored.

- Guide Belt Cleaning: Linked with the printing program for lifting and lowering, reducing the deformation of the scraper, extending the device’s lifespan.

- Nozzle Maintenance: Fully enclosed moisture retention, ink ejection, and scraping device, maintaining stable printing conditions for the nozzle.

- Height Adjustment: The printing cart automatically lifts and lowers, with adjustable height.

- Control System: PLC control system enhances the stability of system operation.

- Ink Supply Method: Negative pressure ink supply system, peristaltic pump reduces bubble generation, with built-in abnormal ink supply protection control.

- Printable Fabrics: Can penetrate fabrics of appropriate thickness, no penetration for thick fabrics.

- Printing Process: Same flower same color, same flower different color, different flower different color.

- Alignment Parameters: Images without recognizable information, assisting manual input of alignment parameters.

- Wrinkle Detection: Detects fabric on the guide belt through sensors, pauses printing upon detecting wrinkles, prompting the customer to address the issue.

- Operation Statistics: Printing log function automatically records and statistics printing operations, facilitating job management.

- Ink Consumption Statistics: Automatically counts ink usage, calculating printing costs.

Interpretation of Control Advantages

- One-time forming double-sided printing structure, has obtained invention patent authorization in regions such as China, Japan, the United States, and the European Union.

- Automatic alignment double-sided printing technology, easily achieving the double-sided printing process for both permeable and non-permeable fabrics.

- No manual intervention required, can provide various printing options such as ‘same flower same color, same flower different color, different flower different color.’